HK968P Automatic Edge Banding Machine

Video ea Sehlahisoa

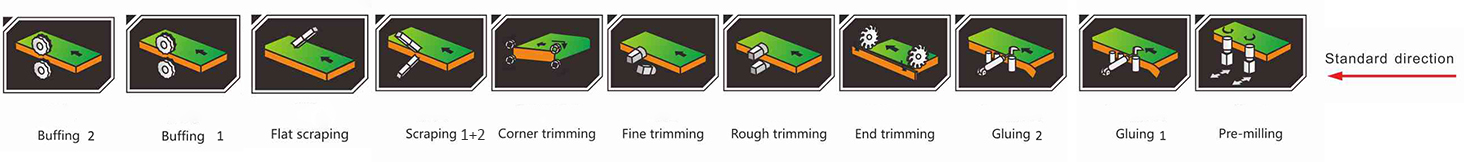

Ts'ebetso ea mantlha bakeng sa mochini ona oa ho kopanya o mohele

* Phatlalatso ea Phanele e Phahameng ea Lebelo

* Touch Screen User Interface

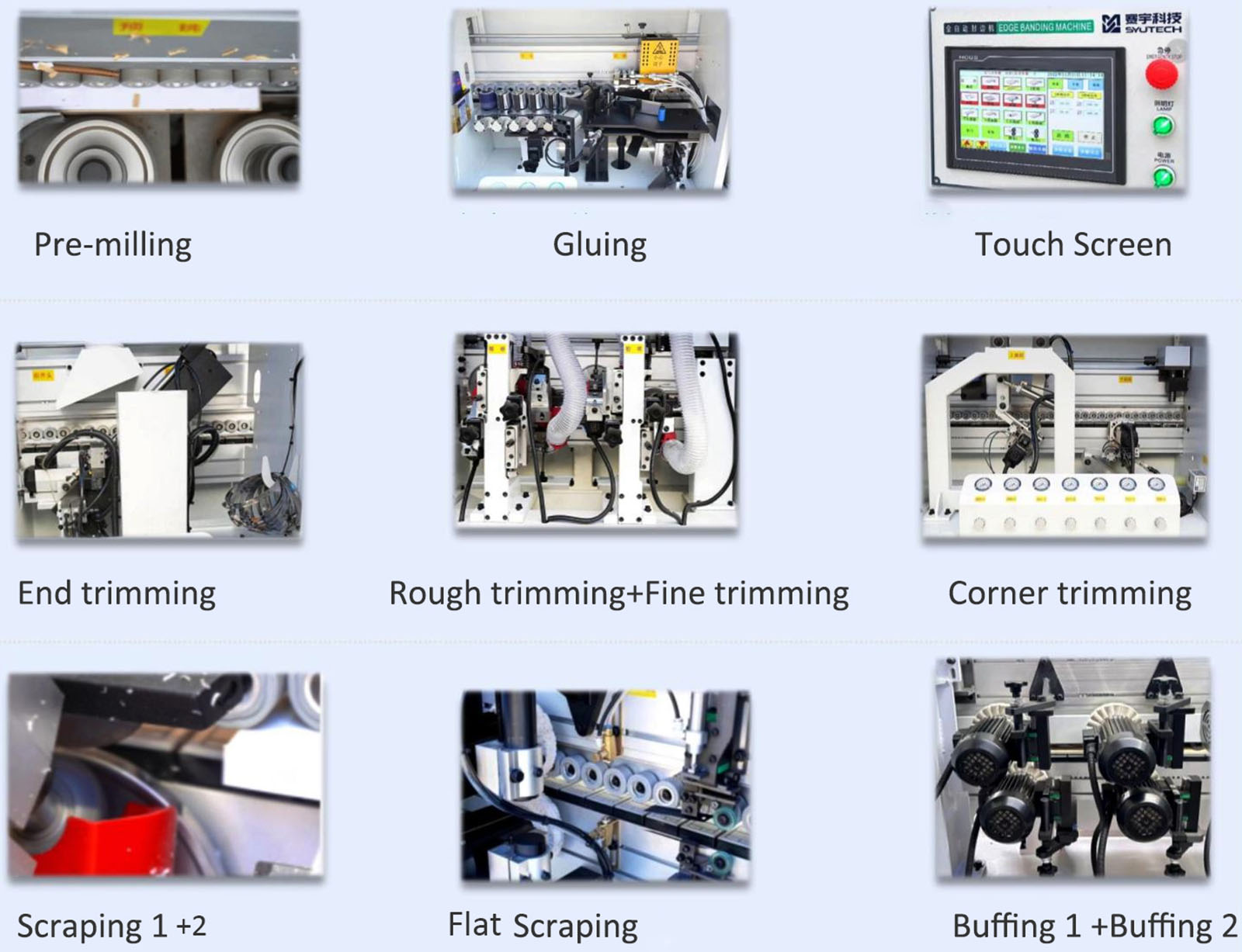

* Ho sila pele (setsi sa ho hloekisa pele ho sona)

* Sekhomaretsi & Khatello

* Habeli Motor End Cut

* Ho khaola ka holimo le ka tlase

* Sekhahla se setle le se ka tlase

* Ho potoloha ka hukung

* Radius Scrape

* Li-Buffers tse kaholimo le tse tlase

Mekhahlelo

| Mohlala | HK968 |

| Bolelele ba phanele | Min.150mm(huku trimming45x200MM) |

| Bophara ba phanele | Min.40mm |

| Bophara ba sehlopha sa moeli | 10-60 limilimithara |

| Botenya ba sehlopha sa moeli | 0.4-3 limilimithara |

| Lebelo la ho fepa | 20-22-28m/min |

| Matla a kentsoeng | 35KW380V50HZ |

| Matla a moea | 0.7-0.9Mpa |

| Boemo ka kakaretso | 9500*1200*1650mm |

Mosebetsi oa Sehlahisoa

Sistimi ea Taolo ea Motlakase ea Huichuan

Sistimi ea taolo ea motlakase ea mochini e amohela khoebo e tsebahalang ea lapeng "Huichuan" PLC le sete e felletseng ea li-converter tsa frequency, tse nang le ts'ebetso e tsitsitseng, mesebetsi e matla, nako e telele, le ho nepahala ho holimo,mefuta ea mochini oa banding

Sistimi ea Taolo ea Motlakase ea Huichuan

Sistimi ea taolo ea motlakase ea mochini e amohela khoebo e tsebahalang ea lapeng "Huichuan" PLC le sete e felletseng ea li-converter tsa frequency, tse nang le ts'ebetso e tsitsitseng, mesebetsi e matla, nako e telele, le ho nepahala ho holimo.

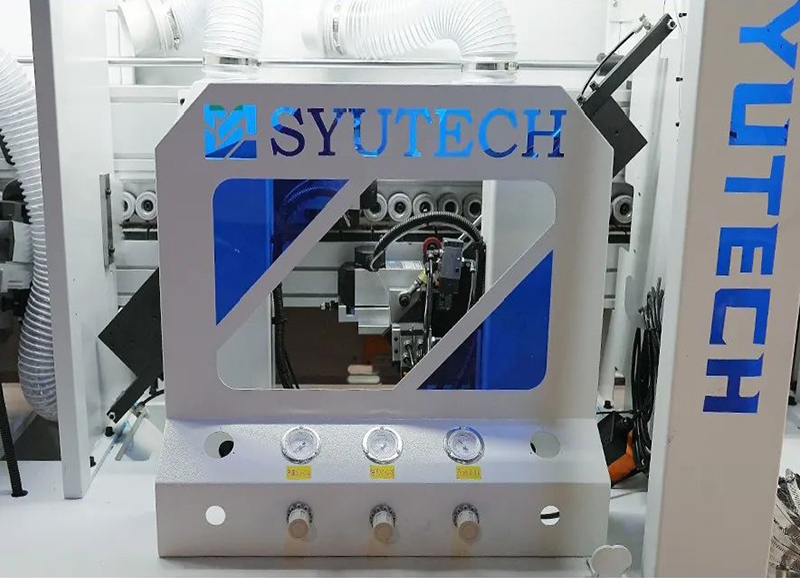

'Mele o boima oa' mele, o teteaneng oa 22mm foreimi, ka mor'a phekolo ea annealing, ha ho bonolo ho fetoha

Mesebetsi e felletseng, lihlopha tse peli tsa sekhechana sa ho qhekella, moeli o bonolo oa khabinete e tiisang 'mele, ho bonolo ho e fetola

Mesebetsi e felletseng, lihlopha tse peli tsa sekhechana sa ho qhekella, moeli o bonolo oa khabinete e tiisang 'mele, ho bonolo ho e fetola

Mesebetsi e felletseng, lihlopha tse peli tsa sekhechana sa ho qhekella, moeli o bonolo oa khabinete e tiisang 'mele, ho bonolo ho e fetola

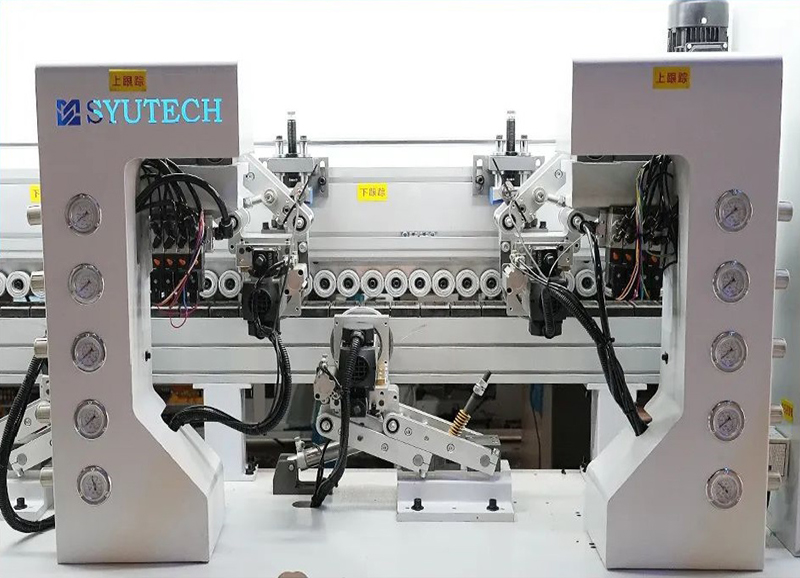

Haisen mofuta o monyane boloko ba ketane ea rolara

Mochini o amohela mabili a manyane a khatello ea Heisen le li-block tsa ketane ho netefatsa tiiso e tsitsitseng le e tšoarellang nakong ea lipalangoang tsa poleiti, ho netefatsa phello ea ho tiisa.

Pitsa ea sekhomaretsi ea mahala ea mebala e 'meli, boloka nako le matsapa 'me u boloke sekhomaretsi ka katleho ntle le tšenyo

Pitsa ea sekhomaretsi ea mahala ea mebala e 'meli, boloka nako le matsapa 'me u boloke sekhomaretsi ka katleho ntle le tšenyo

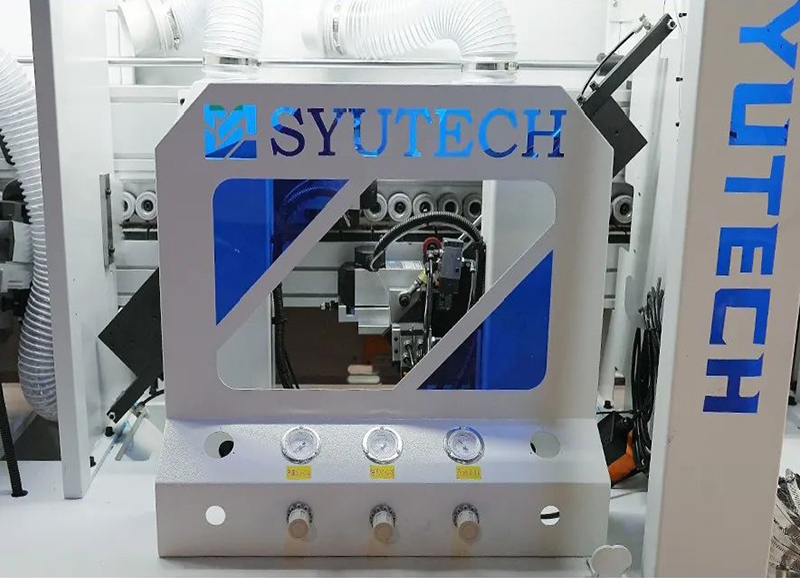

Syutech Patent Ho hloekisoa ha bonolo

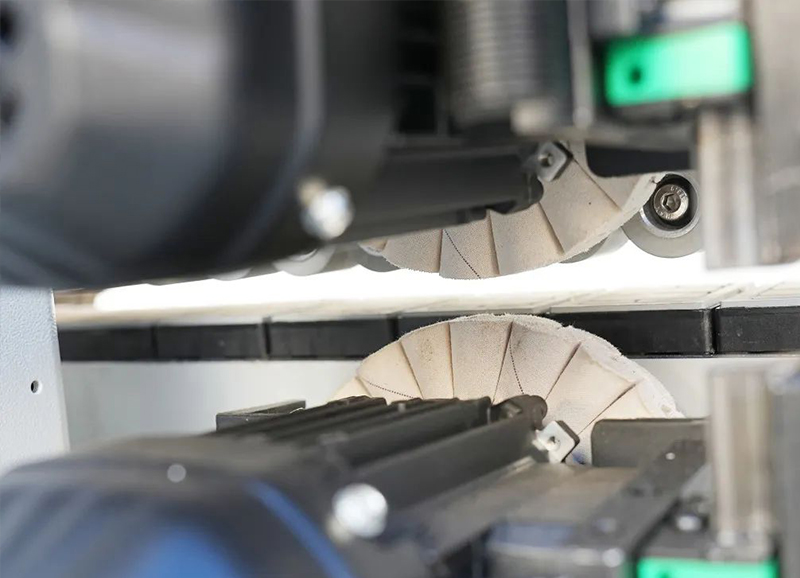

Ho bentša habeli, ho tlosa lerōle le masala a sekhomaretsi, ho boloka bokaholimo bo hloekile

Seporo se habeli se nang le hlooho, se nang le belofo ea ho imolla khatello ka potlako le ka nepo

Seporo se habeli se nang le hlooho, se nang le belofo ea ho imolla khatello ka potlako le ka nepo

ho lata hlooho ea rona, ho tšela lipoleiti le ho koala sekheo ka katleho e phahameng le bophelo bo bolelele ba ts'ebeletso

Mehlala